Collected energy management tips, tricks and resources

|

Technical material:

Building fabric

|

Other information and resources:

Degree-day data (partly free) |

Economic thickness of pipe insulation

Thanks to Hannah Paddock for posing a question about how to calculate the economic thickness of pipe insulation.My advice to her was to get suppliers to provide her with before-and-after calculations of heat loss. I advised checking their sums for reasonableness using common sense (for running hours, boiler efficiency, fuel prices, etc) and a reference book such as Handbook of Energy Data and Calculations (Peter D Osborn, pub. Butterworths 1985) for heat-loss coefficients. If you can't get hold of a textbook then (with caution) try websites such as www.engineeringtoolbox.com/steel-pipes-heat-loss-d_53.html and www.engineeringtoolbox.com/copper-pipe-heat-loss-d_19.html to corroborate their heat-loss assumptions. Hunting around, I did find an on-line pipe insulation calculator but rather annoyingly it does not allow you to specify zero insulation. If it had done, it would have been more useful. I have contacted the author to suggest it. I have since found what looks like a better article at cheresources.com. V.V. 30 October 2006

|

It's sometimes said that a full freezer uses less energy - not true. When the door is closed

and the load is at the required temperature,

all the refrigeration circuit is doing is removing heat that leaks into the compartment

through the insulated walls. The freezer could be full or empty - the rate of heat transfer

will be no different. It will only change if the room temperature changes. You can

detect that it must be dubious advice because of what people suggest for filling the space:

bread (high mass and volume); empty ice-cream cartons (low mass, high volume); and crumpled newspaper

(low mass, low volume). The only thing they have in common is they impede air circulation (of

which more later).

Some people say that by keeping the freezer full, you reduce the amount of chilled air that can spill out. Maybe, but door openings account for only 1 - 2% of annual running costs so the effect is small... In fact one kilowatt-hour of electricity would rechill all the air in a 100-litre freezer about a thousand times. Much more important in causing high running costs are the following:

This myth is almost universal and is promulgated by organisations that should know better. So where did it come from? It probably started with the perfectly true observation that a larger freezer uses more power, so it is unwise to buy one that is bigger than you need. Related to this is the idea that the running costs per pound stored are lower for a freezer that is fuller; but this "operational" efficiency has then been confused with thermodynamic efficiency, which is affected by a lot of things, but not by the loading. Conclusion: store as much or as little as you need; but leave room for air to circulate.

|

|

You may be able to save electricity by voltage reduction if your mains supply voltage is significantly above the statutory minimum. The method works particularly well if lighting is a significant part of your load; motors also benefit. |

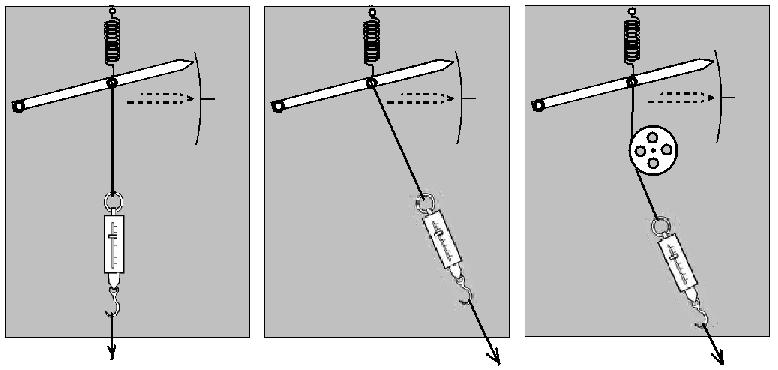

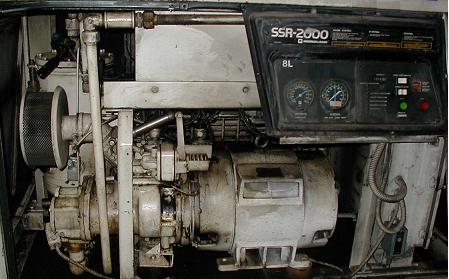

Compressed air systems

|

The US Department of Energy Industrial Technologies Program has a page containing a number of links to free 'tip sheets' on such things as: alternative strategies for low-pressure end uses; storage and control strategies; system maintenance; effect of intake air on compressor performance; minimizing leaks; and other relevant topics. (added 19 March 2006) |

Electrical energy saving exercises

Sequencing fans with VSD

What's the best strategy for part-load operation of a bank of fans with variable-speed drives? Try this simulation. (V.V. 7 Jan 06)True or false?

If you are leaving the room for less than ten minutes, it's cheaper to leave the fluorescent lights on... find out, feeding in your own assumptions about the size and duration of the startup surge. (V.V. 6 Jan 06)Why poor power factor is a problem

If an electrical circuit suffers from poor "power factor", a higher current than necessary will need to be drawn in order to deliver the required power. This can increase power charges, or stress the supply infrastructure: see a simulation of the effect. (V.V. 6 Jan 06)

Sankey diagram softwareThe product recommended by one of our readers in October has been upgraded: click here for feedback from the user and news from the supplier.(V.V. 2 Dec 05) |

|

Automatic controlsControls can have a part to play saving energy for all users from the largest to the smallest. As well as the well-rehearsed topic of controlling heating lighting and other building services, there are often opportunities in industrial situations as well: see article. (V.V. 20/11/05) |

|