Vilnis Vesma

14 January 2008

See also:

Automatic meter reading

Flow metering;

Justifying additional meters

Manual meter reading

The following suggestions, grouped under headings of policy, preparation and practice, will help you ensure that your meter-reading regime is accurate and reliable.Policy

- Decide at what interval to read the meters – monthly or weekly, for example – and set a target reading time such as, say, the first working day of the month, or 7 a.m. each Monday morning.

- Make someone responsible for taking the readings and nominate a deputy to cover for absences

- State how much leeway is allowed on meter-reading date and time.

- If your metering is used for monitoring and targeting or ‘waste-avoidance’ analysis, make arrangements to collect ‘driving factor’ information such as production, degree day figures, etc, at the same intervals as meter readings.

Preparation

- Create a checklist of meters to be read. In the case of multi-rate meters, say which registers are to be read and recorded.

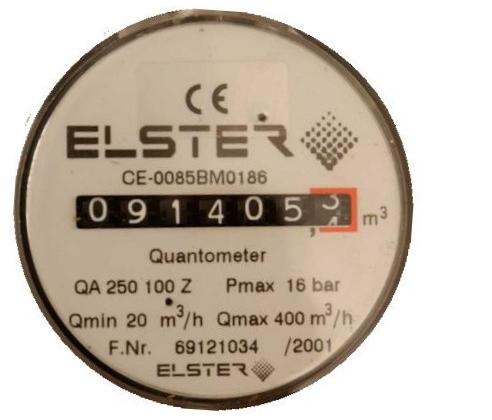

- Record their attributes: what commodity they measure, their location, units of measurement (including any multiplier factor such as x10), number of readout digits, serial number and other salient facts

- Consider fixing a durable label or tag near the meter to identify what it is measuring

- If appropriate, prepare forms on which meter readings can be recorded. Include provision for time as well as date if readings are more frequent than once a month. It is useful to show the meter serial number if known and also any special access requirements (e.g. who holds the keys, swipe card or access codes)

- Take an initial set of readings for the record.

- Brief the nominated meter readers and provide training, especially relating to meters with which they are not familiar

- If possible, disable the reset-to-zero buttons sometimes found on remote readouts.

- Check the security of power supplies to meters and ancillaries (where relevant). If interruptions are a risk it may be necessary either to secure the supply, or read the meter more frequently.

- In the case of natural gas supplies, identify where on the bills the calorific value and the correction factor for temperature and pressure are shown. These will be needed to convert the volumetric gas measurement to energy terms.

Practice

- Read the meters as close as possible to the target day and time

- Check each serial number against that expected

- Always record the date on which each meter reading is taken. If read more frequently than once a month, record the time of reading as well

- Record the reading exactly as it appears on the meter. Show all the digits, and the decimal point if there is one (decimal fraction digits may be indicated by a contrasting colour scheme)

- When meters are exchanged, take readings from both; note the date, and register the attributes of the new meter on the central record.

- Adopt a consistent policy in respect of fixed digits printed after the readout register. If a gas meter for example is labelled as recording cubic feet, but has ‘00’ printed after the readout register, you can either (a) ignore the fixed digits and treat the meter as a hundred-cubic-feet instrument; or (b) treat it as a cubic-feet device and include the trailing ‘00’ on all readings taken from it.

- Gas-meter readings are usually volumetric and must be corrected for temperature and pressure variations -- unless the meter has a built-in corrector -- and for calorific value.

- Remember that the register displayed on most half-hourly electricity meters is not the total units consumed, but rather the cumulative units for the rate band active at the time of reading. Use the button provided to step through the available readout registers to obtain the totals you want.

- On remote readouts with reset buttons, do not reset to zero after reading the meter.

- For unmetered commodities held in bulk on site, record their stock levels at the same time as the readings are taken on meters, and the quantities of all deliveries received since the last stock-level entry.